Determining Spectrophotometer UV Filter Position

in Datacolor

The

UV calibration is necessary to ensure a constant UV emission of the bulb. The

measured reflectance of materials that contain optical brighteners or

fluorescent colorants is

directly affected by the amount

of ultraviolet (UV) energy present in the light source when the material is

measured. In order to accurately measure these types of materials, the amount

of UV energy emitted by the light source of the spectrophotometer must be

controlled. This is accomplished by calibrating the UV filter on the

spectrophotometer using a “Fluorescent Reference Standard” and the “UV

Calibration” program in Datacolor Tools 1.x. The “Fluorescent Reference

Standard” is a white ceramic tile with a red label and is included in the

spectrophotometer calibration kit. This capability is only available on

spectrophotometer equipped with a UV filter. There are several methods that can be used to

calibrate the adjustable UV filter position. Please refer to the whiteness

standard you are using to determine the method to be used.

UV Calibration Procedure(using the Ganz/Griesser method) :

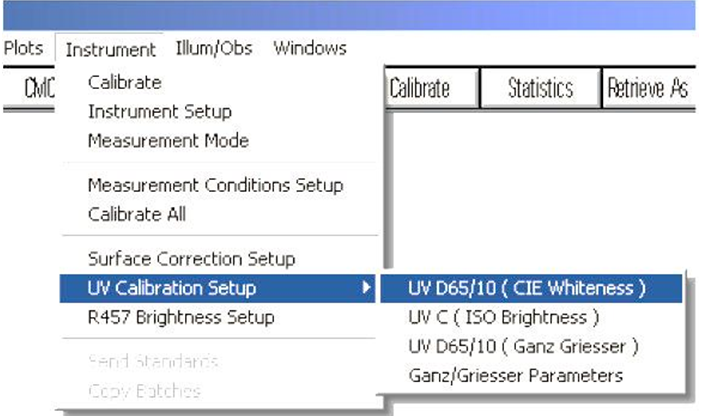

1. Select “ UV Calibration Setup” from the “Instrument” drop-down

menu in Datacolor Tools 1.x and click on the desired UV calibration method: CIE

Whiteness, ISO Brightness, or Ganz Griesser.

2. The Measurement Main Window will be displayed and the specified UV

calibration method will be selected.

3. If using the “Ganz-Griesser” method, the Ganz-Griesser whiteness

parameters must be entered into the software. Click on “Whiteness parameters”

to display the entry form for the Ganz-Griesser whiteness parameters. Click on

“Manual Change”, enter the corresponding parameters from the “Instrument

Ultraviolet Calibration” document, and then click on “OK”.

4.Enter either the “CIE Whiteness” or “Ganz Whiteness” value – such

as 122 or 169 – from the “Instrument Ultraviolet Calibration” document into the

field labeled “Whiteness of test-tile”.

5.Position the “Fluorescent Reference Standard” (the white tile with

the red label) against the instrument, with the sample-holder arm firmly

positioned into the recess on the back of the tile. Click on “Auto-Calibrator”

to begin the UV calibration process.

6. Click on

“OK” to start the UV calibration or “Cancel” to cancel the UV calibration.

7. The UV filter will be automatically adjusted and measurements will

be taken until the appropriate UV filter setting has been determined. Messages

will be displayed for each UV filter adjustment. Click on “OK” when each

message is displayed, or allow the program to automatically proceed. Several

adjustments may be required to in order to achieve the target whiteness value.

8. The final UV filter percentage to be used will be displayed in the

“Using Position (%)” field. The whiteness obtained with this percentage will be

displayed in the “Whiteness Found” field. The difference between the target

whiteness and the actual whiteness will be displayed in the “Whiteness

Difference” field.

9. Click on “Accept” to save the calculated UV filter position. Then

click on “Close” to close the measurement window.

10. Recalibrate the spectrophotometer as directed in steps 1-4, but

use the appropriate UV filter setting as determined by the sample to be

measured and/or the whiteness value to be calculated.

UV Calibration Calibration Methods

Whiteness indices, computed by such software as Datacolor

TOOLS, are used in association with UV-enhanced spectrophotometers such as the

Datacolor 600, 650, Elrepho, and Check PRO. Such indices are used mainly by the

textile and paper industries where whiteness is important, particularly when

optical brighteners are included in the product. An optical brightener enhances

the whiteness of paper or textiles by absorbing the ultraviolet (UV) part of

the daylight spectrum and re-emitting the energy as visible light. This

phenomenon is known as fluorescence. Because whiteness depends on the UV

content of the incident light, whiteness indices rely on careful control of the

UV content of the spectrophotometer‟s light source. Two commonly used whiteness

indices are the Ganz-Griesser whiteness and the CIE Whiteness Index. Material

standards used to calibrate whiteness via these indices include Hohenstein,

AATCC, Paprican, and STFI. This FAQ should lead a user through more details

about the terminology, determination, and limitations of such whiteness indices

and material standards.

Methods

Ganz/Griesser: This procedure

uses the Ganz/Griesser calibration method. The light

source is filtered to simulate

the D65 Illuminant and the Ganz Griesser parameters are

used to calculate the filter

position. In addition, the target whiteness value is based on

10¼ standard observer data.

CIE using

D65/10: The

light source is filtered to simulate the D65 illuminant. This is the

procedure used to perform a CIE

Whiteness evaluation.

ISO Brightness

(C): The

light source is filtered to simulate Illuminant C. This is the procedure

used to perform an ISO Brightness evaluation

Questions and answer about UV

calibration :

What

are optical brighteners?

Optical

Brightening Agents (OBA‟s), also referred to as Fluorescent Whitening Agents

(FWA‟s), are chemicals containing molecules that fluoresce. When they are

applied to white materials they give the material the appearance of being

“whiter than white.”

What is

fluorescence?

Natural

daylight is not limited to the wavelengths of the visible spectrum (400 –

700nm). It includes radiation from the entire electromagnetic spectrum

including the UV. When radiation of the right wavelength strikes a fluorescent

molecule, it excites the molecule and is absorbed by it. As the molecule

returns to its previous state, it emits the absorbed energy as visible light,

rather than heat. In the case of OBA‟s, UV energy is absorbed by the molecule

and re-emitted in the blue region of the visible spectrum, around 450 nm. For

white materials, an increase in the energy reflected in the blue region results

in the white appearing „bluer‟. A „bluer‟ white is perceived as „cleaner‟, but

a white material that has aged or become dirty appears to be yellow and is less

acceptable to the eye. As a result, OBA‟s are commonly added to white fabrics

and other white materials to make them appear „bluer‟ or „cleaner‟.

What is

a UV-enhanced spectrophotometer?

Because

the amount of OBA fluorescence is directly related to the amount of energy

absorbed by the fluorescent molecule, a UV-enhanced spectrophotometer

(generally one based on an integrating sphere) must have a light source that

emits the right amount of ultra-violet light---typical of normal daylight,

which standards bodies have agreed to be CIE Illuminant D65. The light sources

in such spectrophotometers (such as pulsed-xenon light sources) start out by

containing proportionally more UV energy than D65. A variable-position UV

cutoff filter is then used to control the UV so as to simulate D65. The filter

is placed in front of the beam before it enters the sphere.

How

often must I readjust the UV filter in my whiteness-measuring

spectro-photometer?

As an

integrating-sphere spectrophotometer ages, the barium-sulfate coating in the

sphere increasingly absorbs the ultraviolet light emitted from the source.

Also, the UV light emitted from the light source changes with time. To

compensate, you must adjust the filter to control the UV power in the source.

Adjusting the UV filter involves a “UV calibration” procedure that is separate

from the daily calibration routine. Once the UV filter is adjusted, it does not

have to be re-adjusted to measure non- fluorescent samples. However, to measure

whiteness, you must recalibrate the UV-filter setting regularly---we recommend

weekly.

How is

the UV-filter setting calibrated at the factory?

As a rule,

Datacolor no longer calibrates the UV-filter setting at the factory, but offers

a new optional factory calibration service on new instruments for

customer-specified whiteness standards. Datacolor does test every instrument‟s

UV capabilities and performance, so your new instrument is guaranteed to be

able to calibrate to any of the standards mentioned below. It is important for

the customer to decide which of the following UV calibration methods are best

suited for their applications: Ganz-Griesser whiteness using Hohenstein textile

reference specimens, the CIE Whiteness Index using AATCC textile reference

specimens, the CIE Whiteness Index using appropriate paper reference specimens

(Paprican, STFI, or other), and ISO Brightness using the above-noted paper

reference specimens. (See FAQ 12.)

What is

the purpose of the fluorescent tile?

The

fluorescent tile is intended as a transfer (or working) standard to allow the

user to update the calibration after first calibrating with the appropriate

primary-reference specimens. The tile is useful because it is less fragile than

the primary reference specimens, so its measurements can be trusted for a much

longer time. To use the tile, measure its whiteness values immediately after

the primary-reference calibration using the filter settings and instrument

values determined from that calibration. From these measurements, you can

assign up to four different whiteness values to a fluorescent tile. The values

are the following: (a) The Ganz-Griesser whiteness measured at the

Ganz-Griesser filter setting (the associated instrument parameter values being

automatically inherited from the Hohenstein calibration); (b) the D65/10o CIE

Whiteness Index measured at the paper-standard (e.g., Paprican) filter setting;

(c) the reference ISO Brightness at the setting for which C/2o CIE Whiteness

Index is measured; and (d) a legacy D65/10o CIE Whiteness Index measured at the

Ganz-Griesser filter setting. [Before 2004, only the Ganz-Griesser procedure

was used to perform UV calibration, and that accounts for the legacy value for

CIE Whiteness. Some textile customers may still need this setting.] The

schedule of filter-setting calibration should be integrated with a longer

schedule for replacing your primary standards such as Hohenstein, Paprican,

STFI, or AATCC. Generally such replacement should be done annually, although in

some cases a 3-month replacement cycle is recommended.Below is a common

practice for UV calibration that incorporates both the primary (absolute

whiteness) standard and the transfer (working) standard:

1.Set

the measurement conditions of the instrument system as found in the

primary-standard documentation.

2.

Perform the usual Black and White Calibration.

3.Calibrate

the instrument for UV using the primary standard.

4.(UV)

Characterize the UV working standard (fluorescent tile).

5.Enter

the obtained Whiteness value in the software as the UV standard target (IST)

value.

6.Until

the next Absolute UV Calibration, weekly calibrate the instrument for UV using

the UV working standard.

For Ganz-Griesser calibration, how should I later

use the the values I first measured with the fluorescent tile?

. The values you will use comprise

option (a) of FAQ 5. In the “UV Calibration Setup” menu of Datacolor TOOLS,

select “UV D65/10 (Ganz Griesser).” Type the Ganz-Griesser whiteness. The

instrument constants you obtained from the first calibration will appear with

an option to edit them, but do not edit them. With the fluorescent tile in

place for measurement, allow the auto-calibration function to adjust the UV

filter until the measured value satisfies a criterion. In all strictness, user

calibration should always be done with a set of Hohenstein reference specimens

(which have a lifetime of 90 days). Use of the fluorescent tile assumes that the

Ganz-Griesser constants are indeed constant for the instrument, but a true

recalibration (through “Recalibrate Parameters” in the Ganz-Griesser menu) will

not make this assumption.

For

D65/10o CIE Whiteness, how should I later use the values I first measured with

the fluorescent tile?

If you are

interested in paper or board under outdoor illumination, you will need the CIE

Whiteness Index corresponding to Standard Illuminant D65 and 10-degree Standard

Observer. In the “UV Calibration Setup” menu of Datacolor TOOLS, select “UV

D65/10 (CIE whiteness).” With the fluorescent tile in place for measurement,

enter the CIE D65/10 Whiteness under “Paprican” (option (b) of FAQ 5), and

allow the auto-calibration function to adjust the UV filter until the measured

value becomes the same as the target value. In all strictness, recalibration

should be done with a Paprican paper standard using the method in ISO standard

11475. To calibrate with a Paprican standard, type the reference CIE Whiteness

for that standard in the field where you would have typed the reference value

for the white fluorescent tile.

For

C/2o CIE Whiteness, how should I later use the values I first measured with the

fluorescent tile?

If you are

interested in paper or board under indoor illumination, you will need the CIE

Whiteness Index corresponding to Standard Illuminant C and 2-degree Standard

Observer. To calibrate the UV-filter setting in your instrument to C/2o, choose

“UV C (ISO Brightness)” in the “UV Calibration Setup”. If you want to update

calibration with the tile, type in the value from option (c) of FAQ 5. If not

(or if you want a more rigorous calibration), then procure a Paprican reference

specimen, type its ISO Brightness in the same field where the option-c value

would have been entered, and perform a rigorous calibration by the method of

ISO standards 11476 and 2470. After calibration, you can measure either ISO

Brightness (also called R457 Brightness) or C/2o CIE Whiteness with your

instrument. [Note: ISO Brightness is used to set the UV filter for C/2o CIE Whiteness

measurements, but the two numbers are not the same. The former requires a

reflectance spectrum and imposes a special blue weighting function, but the

latter is computed from colorimetric x,y values.]

How can

I use the legacy CIE Whiteness value option (d) in FAQ 5?

The value

denoted “CIE Whiteness” or “D65/10 CIE Whiteness” under Ganz-Griesser

calibration is a legacy value. It was included specifically for the textile

industry when the only UV calibration was Ganz-Griesser (before 2004). Use of

this value is not recommended except to compare with previous uses of the

index.

How do

I proceed if I need a new fluorescent tile?

If you

lose the fluorescent tile or it is damaged, a replacement tile is available,

but its reference values must be obtained on your particular spectrophotometer.

To do this, order the appropriate primary-reference specimens (e.g., Hohenstein

or Paprican), recalibrate your instrument with these, and record the

appropriate readings on the new tile.

Is it

legitimate to compare pre-2005 with post-2005 Hohenstein-based whiteness

values?

One must

first impose an adjustment (directed by Hohenstein) from the new whiteness

value back to the old one: (Wold = 0,95 Wnew + 12). That adjustment was

necessitated by a re-calibration of the Hohenstein samples referenced to NRC in

Canada. Going forward, whiteness values should be the new ones, but comparison

with the old ones should be done with the adjustment formula. Because of this

situation, Hohenstein‟s adjustment is not implemented in any Datacolor

software; Adjustment is the responsibility of anyone seeking to compare

post-2005 with pre-2005 values. Note that, prior to April 11, 2006, the GG

whiteness value written on the Datacolor fluorescent tile is adjusted---i.e.,

“old.” After that date, the reported GG whiteness value is unadjusted---i.e.,

“new”.

Is it

legitimate to compare whiteness values for different instrument geometries?

Even for

the same instrument model, unit-to-unit differences can occur within a

tolerance of 2 whiteness units. Differences in instrument geometry or optics

can necessitate enlarging this tolerance. Therefore, it is not advisable to

compare whiteness index results from instruments with different geometries

Why

can’t I simply take my fluorescent tile and its Ganz-Griesser Whiteness value

to another instrument?

Ganz-Griesser

Whiteness measurements rely on a set of parameters that are

instrument-specific. These parameters are calculated during the Ganz-Griesser

absolute UV calibration with Hohenstein standards. It is significant in this

regard that Ganz-Griesser calibration is done with four Hohenstein standards

that have different degrees of optical brightening. That calibration determines

three instrument parameters as well as the Whiteness value. If you change the

instrument, you must find the instrument-parameter values using the full

calibration procedure. Then you can take the Whiteness value as given.

Why do CIE and Ganz-Griesser/Hohenstein whiteness

values disagree?

First,

some background: Paprican, STFI, and three others manufacture reference paper

specimens to be used in evaluating CIE whiteness; Hohenstein manufactures

textile reference specimens to be used in evaluating Ganz-Griesser (GG)

whiteness. Both CIE whiteness and GG-Hohenstein whiteness involve simulating

D65 from a spectrophotometer light source by partially interposing a UV filter

with a cutoff at 400 nm. In each case, the user adjusts the UV-filter setting

(amount of interposition) guided by measurements of a reference specimen.

Because GG and CIE have different calibration algorithms and different

fluorescent agents in their reference-specimens, there is no reason to expect

them to yield the same UV-filter setting. Therefore, no comparison is justified

between these standards: e.g., Paprican-CIE should be used for paper and

Hohenstein-GG should be used for textiles, as intended.

Is it

legitimate to compare whiteness values for different apertures and

specular-included/excluded settings on the same spectrophotometer?

No. The

calibrations made for whiteness/brightness applications must be made at the

same aperture size and (for d/8 spectrophotometers) specular excluded/included

setting as for subsequent measurements. For example, if a spectrophotometer is

UV-calibrated at LAV, then subsequent measurements will apply only for LAV.

Also, if the calibration is made specular-excluded (for d/8 geometry spectros),

then subsequent measurements will apply only for specular excluded. The

measurement conditions become more stringent if you use the calibration numbers

on a certificate provided with a white-tile transfer standard (see attached

specimen). In that case, the transfer-standard calibration condition of LAV (or

XLAV) and specular-excluded (announced on the certificate) must be used in

subsequent measurements.

Generally,

we prefer LAV and specular-excluded for UV calibration and measurement, so as

to minimize the effect of sphere coloration on the measurement. Also, LAV

increases the repeatability and reproducibility of the measurement. However, so

long as all the measurements in a supply chain (including transfer-standard

calibrations) are made with the same viewing conditions, comparisons are valid.

Should

I expect whiteness values to be as accurate as other spectrophotometer-derived

measurements?

No.

Despite whiteness calibration, the method has inherently unreliable results on

test specimens. This occurs partly because the D65 adjustment does not achieve

a true spectral match to D65, and partly because the test specimen perturbs the

color of the sphere (especially a small sphere for which the port size is an appreciable

fraction of total sphere area). Because of these factors, published tolerances

of GG whiteness are large (lenient). We should live with the leniency,

cognizant of the intrinsic limitations of the method.

Where

can I find out more about Datacolor’s whiteness evaluation?

Depending

on the Datacolor product you have, you can consult the “UV Calibration and

Whiteness Options” chapter in either of the following manuals:

Datacolor

TOOLS User Guide Part No. 4220-0927M Rev 1, April, 2005

Datacolor

CHECK Manual Part No: 4230-0396M, April 2005

Both these manuals

describe how to use the UV calibration feature in the relevant Datacolor

product, and the use of the Datacolor product to perform whiteness evaluation.

PTIS Calibration services is nationally recognized for superior calibration and repair of radiation detection instruments used in a variety of medical and industrial applications.

ReplyDelete